Manufacturing is one of the most vital industries in the world. It is responsible for creating the products we use daily, from our clothes to the food we eat. However, manufacturing is a complex and challenging process, making it one of the most labor-dependent industries. Manufacturers rely heavily on workers to ensure that products get produced efficiently and of high quality.

There are many manufacturing jobs, from assembly line workers to engineers. Employment in manufacturing comes from various settings, from small businesses to large factories. Manufacturing is an essential part of the economy, one of the few industries challenging to outsource. It means that manufacturing jobs are some of the most stable and secure employment in the economy.

However, that doesn’t stray away from the fact that the industry has its challenges. Manufacturers’ most significant challenge is constantly adapting to new technologies. New technologies develop frequently, and manufacturers must stay on top of the latest trends to maintain a competitive edge. They also need to be able to adapt their processes to incorporate new technologies quickly. It can be challenging, as it requires a high degree of flexibility from workers.

However, incorporating technology can happen slowly. Here are a few initial steps to take.

Manufacturing Automation

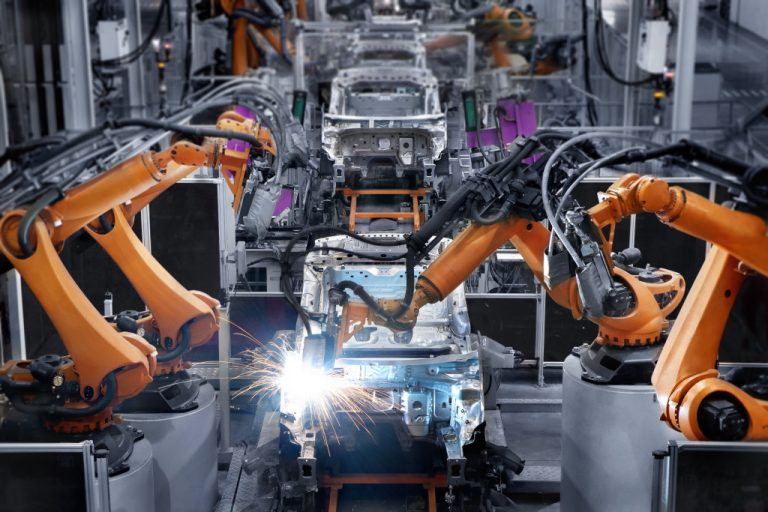

Manufacturing is a complex process that relies heavily on human labor. However, this can lead to mistakes and errors during the production process. Automation can help to reduce these errors, as it can help to automate the tasks that humans carry out. It can lead to a more efficient and accurate manufacturing process.

Automation can also help to improve safety in the workplace. Many of the tasks carried out in a manufacturing setting can be dangerous, as they involve working with hazardous materials or machinery. Automation can help reduce the chances of an accident, as it removes the need for humans to carry out these tasks.

Overall, automation can be a valuable tool for manufacturers. It can help to improve efficiency and accuracy in the production process, and it can also help to improve safety in the workplace.

Online Suppliers

Manufacturing is a complex process, and it’s crucial to partner with suppliers to get the best products. However, it can be challenging to partner with suppliers in person. It can be time-consuming and expensive to travel to meet with potential suppliers.

However, it’s now possible to partner with suppliers online using technology. Many online platforms connect manufacturers with suppliers. It allows manufacturers to find and compare suppliers easily, making partnering with a supplier faster and more efficient.

Technology has also made it easier for suppliers to connect with manufacturers. Many suppliers have their website or online store where they sell their products. It allows manufacturers to browse and order products from the comfort of their own office or factory. You can find affordable construction equipment for sale, saving you the trouble of going through the manual process of going to different companies to compare and negotiate rates.

Technology has made it easier and more efficient to connect with suppliers. Finding and partnering with suppliers online is now possible without meeting in person.

Manufacturing Software

Manufacturing software is essential for any manufacturer. It helps to improve the production process, as it can automate tasks and help to improve accuracy. It can also help to improve safety in the workplace.

Software is also crucial for tracking and managing inventory. It allows manufacturers to keep track of what products they have in stock and help plan future production runs. It is vital to ensure that the factory never runs out of products, and it can help to optimize production runs.

Finally, the software is vital for tracking orders and shipping. It can help to ensure that products get shipped on time and that customers are always happy with their demands.

An inventory management system might apply to warehousing, stockroom operations, and manufacturing processes.

Technology has transformed manufacturing. It has made it easier to connect with suppliers and customers, and it has also made it easier to track inventory and production. Manufacturing software is essential for any manufacturer, as it helps to automate tasks and improve accuracy.

Cloud Computing

Cloud computing is a relatively new technology that is starting to transform manufacturing. It allows manufacturers to store data and applications in the cloud, making it accessible worldwide.

Cloud computing can help manufacturers to improve collaboration between different departments. For example, if the design team gets based in one country and the production team is based in another, they can still work together on the same project using cloud-based applications.

Manufacturing software is crucial for any manufacturer. It helps to improve the production process by automating tasks and increasing accuracy. It also allows manufacturers to keep track of inventory, optimize production runs, and track orders and shipping.

Conclusion

Technology has made it easier for manufacturers to connect with suppliers, automate tasks, and improve accuracy in the production process. It has also helped to improve safety in the workplace. Overall, technology can be a valuable tool for manufacturers. Manufacturers must stay on top of the latest trends to maintain a competitive edge and be able to adapt their processes quickly to incorporate new technologies.