3d printing is a unique piece of technology that takes advantage of the fact that the world is now digital. With a 3D printer, you can create a physical object from a digital file. So, for example, you can design anything you want and print it out in 3D.

3D printing is often used for prototyping or creating custom parts for machines. However, companies can also use it to create artwork or other objects. The possibilities are endless with 3D printing.

The versatility and affordability of 3D printers make them a great tool for small businesses or even individuals. It’s also one of the main reasons it’s affecting so many industries worldwide. Here’s how 3d printing impacts various industries such as the manufacturing, engineering, and even orthodontics industries worldwide.

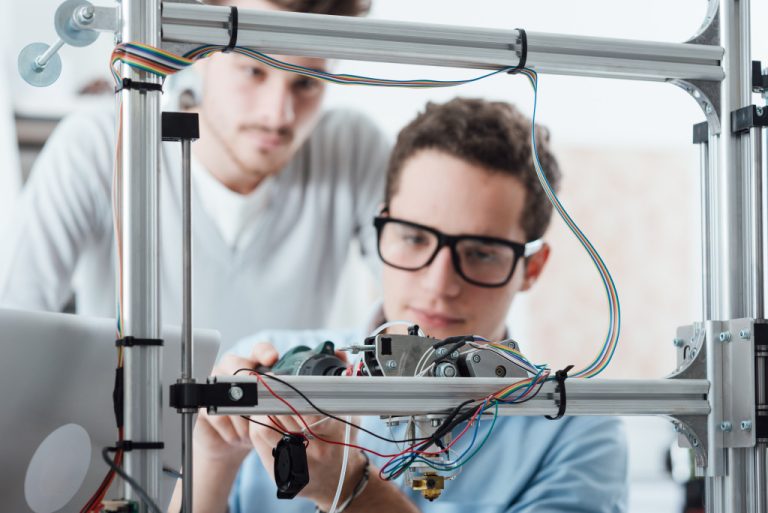

Engineering

The engineering world has been waiting for technology like 3d printing for a long time. 3D printing gives engineers the ability to quickly prototype and tests new designs. This process is known to be rapid prototyping.

Rapid prototyping is a massive advantage for engineers because it saves time and money. In the past, engineers would have to create a physical model of their design, which could take weeks or even months. With 3D printing, they can print out a prototype in hours. This speed is essential for engineering companies that need to get products to market.

Traditional engineering methods require that parts be made in large quantities and to specific sizes and shapes. This can often lead to wasted material and time. With 3D printing, you can create custom parts specific to your needs. This saves time and money and shows that 3D printing in engineering will only increase as the technology gets better and more affordable.

Manufacturing

Manufacturing is one of the biggest sectors in the United States, and 3D printing is also having a significant impact on it. One of the biggest advantages of 3D printing for manufacturing is that it doesn’t require expensive tooling.

The reduction of tooling in manufacturing companies can produce small batches of products without incurring a lot of costs. It’s perfect for companies just starting out or for companies that want to test a new product before mass-producing it.

3D printing is also changing the way products are made. In the past, most products were made with a subtractive manufacturing process. This process involves taking a piece of material and cutting or machining it into the desired shape. With 3D printing, you can use an additive manufacturing process.

The additive manufacturing process is when you add material to create the desired shape. It is often done with a 3D printer by depositing layers of material until the object is complete. The additive manufacturing process is usually faster and less wasteful than subtractive manufacturing.

Orthodontics

3D printing is also having an impact on the orthodontics industry. Orthodontists are now using 3D printers to create custom braces and other dental devices.

3D printing gives orthodontists the ability to create braces specifically designed for each patient’s mouth. This level of customization is not possible with traditional braces.

Orthodontists can also use 3D printing to create retainers, mouthguards, and implants. 3D printing in orthodontics is expected to grow as the technology gets better and more affordable.

The great versatility of 3d printers can make a difference in individual practices. A dentist office with a 3d printer is more likely to be more efficient and profitable than one that does use it. However, it doesn’t mean that clinics that don’t have this piece of technology would fail. The usage of 3d printers can be quite costly and, when not done right, can lead to more expenses for the clinic.

Automotive

3D printing is also making its way into the automotive industry. Automotive companies are using 3D printers to create prototypes and parts for cars.

3D printing gives automotive companies the ability to quickly and cheaply create prototypes of new car designs. This is essential for companies that need to test new designs before production.

Automotive companies are also using 3D printers to create parts for cars. This includes things like dashboards, door panels, and even engines. 3D printing in the automotive industry is expected to grow as the technology gets better and more affordable.

3D printing is a versatile technology that is having an impact on many industries worldwide. The manufacturing, engineering, orthodontics, and automotive sectors are just a few sectors that are being transformed by 3D printing. As the technology gets better and more affordable, we can see even more industries being impacted by this revolutionary technology.